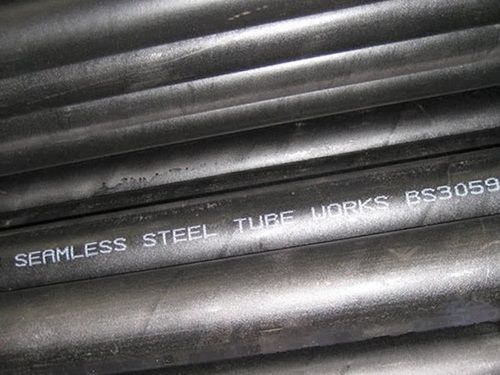

Boiler Tubes

Product Details:

- Product Type Boiler Tube

- Material Carbon Steel

- Type Seamless

- Shape Round

- Technics Hot Rolled

- Surface Treatment Galvanized

- Standard ASTM A192

- Click to view more

Boiler Tubes Price And Quantity

- 100 , , Meter

- 800.00 - 900.00 INR/Meter

Boiler Tubes Product Specifications

- Galvanized

- Seamless

- ASTM A192

- Hot Rolled

- Round

- Black

- A192

- Boiler Tube

- Carbon Steel

- Up to 12 Meter

Boiler Tubes Trade Information

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 , , Meter Per Day

- 3-4 Days

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- All India

Product Description

The boiler tubes are used as the part of energy type equipment such as boilers, steam super-heaters, steam pipelines and similar equipment. It is made from heat resisting carbon and low alloyed steel which can withstand load at high pressure and temperature. We offer these tubes in wide range of sizes and wall thicknesses both in seamless and welded tube form,which is mostly used in steam generators.

Our offered Boiler Tubes are extremely durable and can sustain adverse external conditions. These tubes are suitable for ventilation, power generation and heating purposes. Our tubes are resistant to abrasion and can be fitted easily to the application area. We offer these Boiler Tubes at most affordable prices to our precious customers.

Premium Quality Seamless Boiler Tubes

Our seamless boiler tubes are crafted from high-grade Carbon Steel, ensuring robust performance and longer service life. Meeting ASTM A192 standards, they are suitable for high-pressure boilers and other demanding industrial uses. With hot rolled construction and galvanized surfaces, these tubes deliver consistent quality and enhanced resistance to corrosion.

Versatile Applications and Reliable Supply

These round boiler tubes are used across power plants, refineries, and industrial heating systems. Available in lengths up to 12 meters, they are engineered to withstand high temperatures and pressures. We cater to both domestic and international markets, guaranteeing timely supply from our India-based manufacturing facilities.

FAQs of Boiler Tubes:

Q: What are the primary applications of ASTM A192 seamless carbon steel boiler tubes?

A: ASTM A192 seamless boiler tubes are primarily used in high-pressure boilers, heat exchangers, and superheaters within power plants, refineries, and industrial heating systems due to their superior strength and resistance to high temperatures.Q: How are your carbon steel boiler tubes manufactured?

A: Our boiler tubes are produced using the hot rolled seamless method, which involves heating steel billets and rolling them into round shapes, followed by galvanizing the surface to enhance corrosion resistance and durability.Q: When can I expect delivery for bulk orders of seamless boiler tubes from India?

A: Bulk orders are generally fulfilled within a few weeks, depending on quantity and customization requirements. As an established exporter and supplier in India, we ensure timely shipment to both domestic and international clients.Q: Where do you export your ASTM A192 boiler tubes?

A: We export our ASTM A192 seamless boiler tubes to various countries worldwide, with a strong presence in markets requiring high-quality boiler components, such as Southeast Asia, the Middle East, Europe, and Africa.Q: What are the benefits of choosing galvanized surface treatment for boiler tubes?

A: A galvanized surface provides a protective zinc coating that significantly enhances corrosion resistance, extends tube lifespan, and ensures reliable performance in harsh environments.Q: How should these seamless boiler tubes be maintained for optimal performance?

A: Regular inspection for signs of wear or corrosion, timely cleaning, and prompt replacement of damaged sections will help maintain peak performance and safety in your boiler system.Q: Why is seamless construction preferred for boiler tubes in industrial applications?

A: Seamless tubes offer uniform strength, eliminate the risk of weld failure, and enable better heat transfer, making them ideal for demanding applications in high-pressure and high-temperature environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+